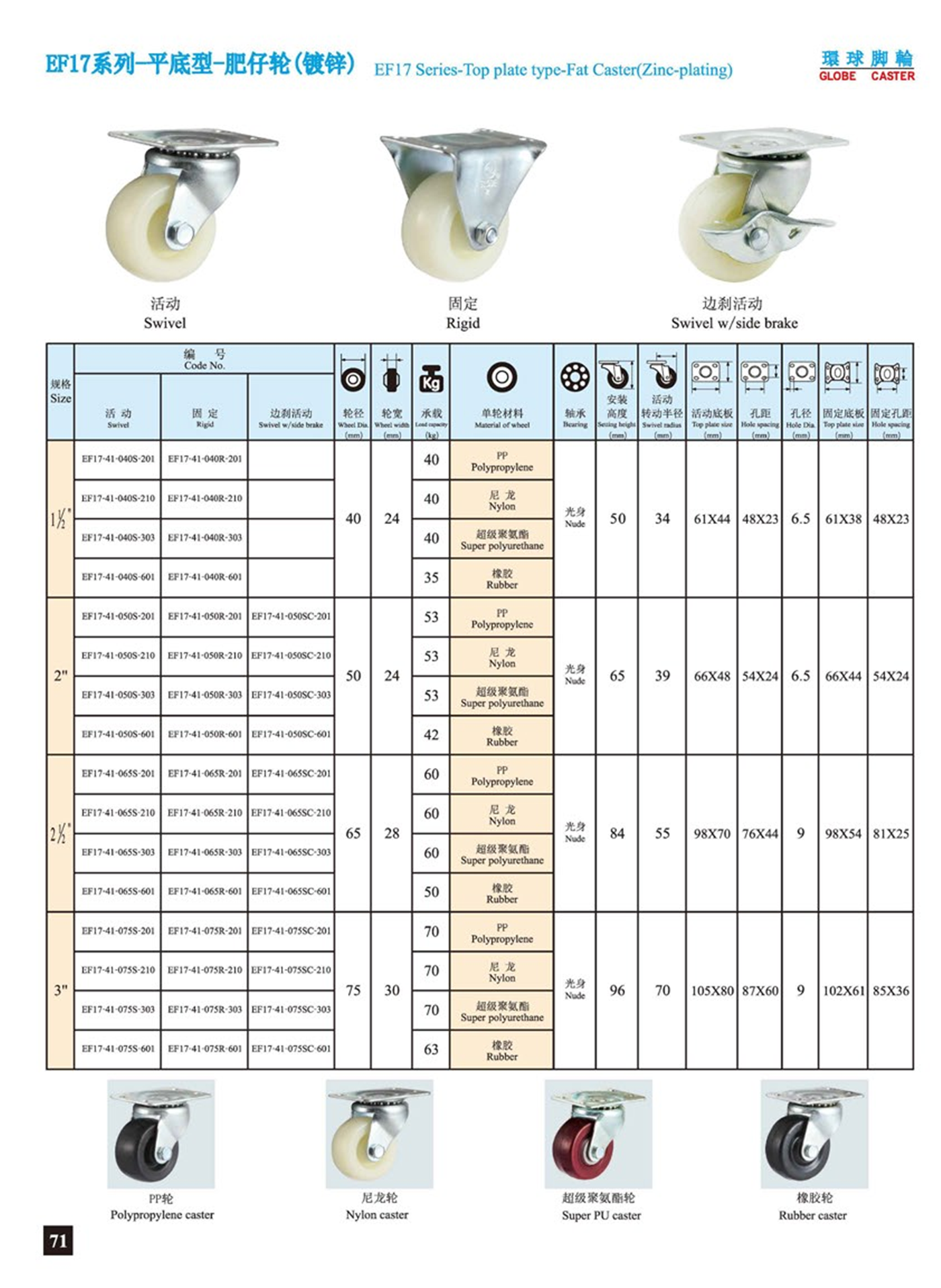

Ipleyiti ephezulu yePP/Nayiloni/PU/Amavili eRubber Fat Castors – EF17 SERIES

1. Izinto ezikumgangatho ophezulu ezithengiweyo ngetshekhi engqongqo esemgangathweni.

2. Imveliso nganye ihlolwe ngokungqongqo phambi kokupakisha.

3. Singumvelisi oqeqeshiweyo iminyaka engaphezu kwama-25.

4. Umyalelo wetyala okanye ii-odolo ezixubeneyo zamkelwa.

5. Iiodolo ze-OEM zamkelekile.

6. Ukuhanjiswa ngokukhawuleza.

7) Naluphi na uhlobo lwe-casters kunye namavili lunokwenziwa ngokwezifiso.

Samkela itekhnoloji ephezulu, izixhobo kunye nemathiriyeli ekumgangatho ophezulu ukuqinisekisa ukuguquguquka, ukulungeleka kunye nokuqina kweemveliso zethu. Kwiimeko ezahlukeneyo, iimveliso zethu zinokunxiba, ukungqubana, ukubola kweekhemikhali, ukumelana nobushushu obuphantsi / obuphezulu, ukungabikho komkhondo, ukukhuselwa komgangatho kunye neempawu zengxolo ephantsi.

Uvavanyo

Iworkshop

1. Hlalutya ekukhethweni kweebrakethi ze-caster ukukhusela imiqadi kunye neentsika ekubiweni.

Izibiyeli zeCaster zihlala zisebenzisa izibiyeli ezenziwe inaliti okanye izibiyeli zentsimbi. Imveliso yezibiyeli ezibunjiweyo zenaliti incinci, isetyenziswa ikakhulu kushishino lwefenitshala yecaster kunye neshishini le-caster yezonyango. Ngoko ke, asiyi kuphinda apha. Siza kugxininisa kuhlalutyo lwezibiyeli zetsimbi. Uhlalutyo lwembonakalo. Ubukhulu besibiyeli sentsimbi ye-caster yi-1mm okanye ngaphantsi ukuya kwi-30mm okanye ipleyiti yensimbi enzima, eyona nto inqunywe ngokweemfuno zomthwalo we-caster.

Abavelisi be-caster besiqhelo basebenzisa iipleyiti zentsimbi zangaphambili, ngelixa iifektri ezincinci zihlala zisebenzisa iipleyiti zentloko kunye neepleyiti zomsila ukunciphisa iindleko. I-head plate kunye ne-tail plate ngokwenene imveliso engaphantsi kwi-steel plate. Ubunzima bentsimbi yentsimbi yentloko kunye nomsila kunye nentloko kunye nomsila awufani. Ixabiso leplate yensimbi nayo ikude kwi-motherboard, kunye nokusebenza kweemveliso ze-caster (ezifana nokubonakala kunye nomthwalo) nazo zihluke kakhulu.

2. Hlalutya ubungakanani be-caster bracket ukukhusela iikona

Ukuze kugcinwe iindleko, iifektri ezininzi ezincinci ze-caster zinciphisa ngamabomu iimfuno zeepleyiti zensimbi. Umzekelo: ii-caster ezine-frequency ephezulu kunye nokusetyenziswa okukhulu kwimarike ye-caster yasekhaya ziyi-intshi ezi-4 (ububanzi be-100mm), i-intshi ezi-5 (ububanzi be-125mm), i-intshi ezi-6 (ububanzi be-150mm), i-intshi ezi-8 (ububanzi be-200mm) i-caster, le caster Z iqala Iveliswa ngokwemikhwa yokusetyenziswa kwe-United States kwaye ibizwa ngokuba yi-caster yaseMelika. Ubuninzi bentsimbi yentsimbi ngokuqhelekileyo isetyenziselwa i-6mm yensimbi (kodwa ngenxa yokuba i-plate yensimbi eqhelekileyo kwilizwe lethu ngokuqhelekileyo ukunyamezela okungalunganga), ubukhulu bentsimbi yensimbi kufuneka bube yi-5.75mm kubavelisi be-caster abaqhelekileyo. Iifektri ezincinci ze-caster zihlala zisebenzisa i-5mm okanye i-3.5mm, iipleyiti zensimbi ze-4mm ukunciphisa iindleko, eziya kukhokelela ekusetyenzisweni kwee-casters. Ukusebenza kunye nokhuseleko factor kuncitshiswe kakhulu.

3. Hlalutya unyango olungaphezulu lwesibiyeli ukuthintela ukutshaja.

Ii-caster ezikumgangatho ophezulu eziveliswe yifektri yesiqhelo ye-caster inomgangatho omhle kwaye akukho burrs. Ngelo xesha, ukwenzela ukuba kuqinisekiswe unyango oluchasene ne-corrosion ye-bracket yensimbi, i-caster bracket yenziwe ngokubanzi nge-electro-galvanized (kubandakanywa ne-electro-galvanized white zinc, blue-white zinc, color zinc, kunye ne-gold-resistant galvanized), ukutshiza, ukutshizwa, ukuntywiliselwa, njl njl. Ukuze kuphuculwe ukunamathela kwentsimbi ye-electro-galvanized, iifektri ze-caster eziqhelekileyo zihlala zisebenzisa i-shot peening, kwaye i-casters echanekileyo ngakumbi iya kusebenzisa ukuguqa kwe-vibration ukuphelisa ngokufanelekileyo i-burrs ebangelwa ukunyathela kunye ne-welding. Ngexesha elifanayo, kunokubonelela ngcono ukunamathela kwe-anti-corrosion layer ebusweni be-caster.